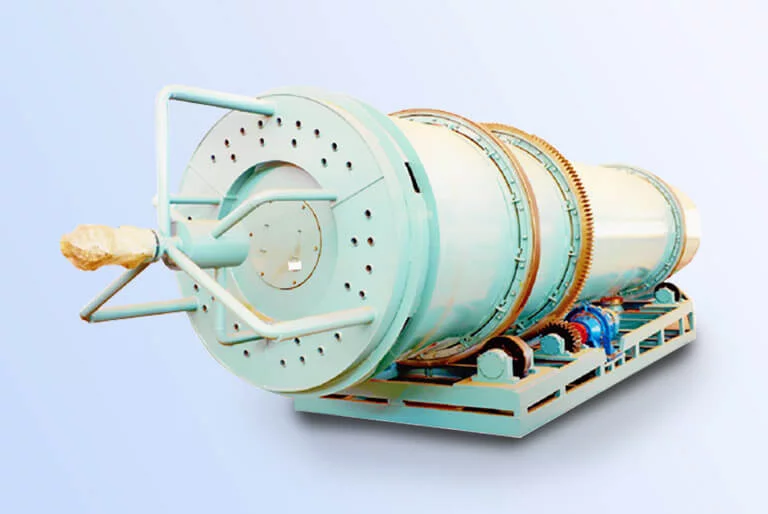

Softening Steam cooker is mainly used in softening and drying of raw material, increasing the plasticity of raw material, decreasing the water content of raw material, making flake thin and not broken. Then, the effect of cooking, pressing, and extraction can be strengthened.

Advantages of RHG horizontal rolling soften cooker.

- The turning of the roller makes the material turn more evenly and avoids material burning. The softening of the material is even and smooth.

- Energy consumption is greatly reduced. Compared with the softening equipment of the same production, the installed capacity of the machine is one-tenth of the vertical softening cooker, so the production cost is also reduced greatly.

- The equipment has a long service life, low breakdown rate, and low maintenance cost.

- Adopting a new design and material control is very convenient. The softening time of material can be adjusted at any time according to different varieties and properties of material.

| Model | Capacity(t/d) | Power(kw) | Rotate speed(m/s) |

|---|---|---|---|

| WRHG120 | 80 t/h | 3 kw | 1-4 m/s |

| WRHG160 | 250 t/h | 7.5 kw | 1-4 m/s |

| WRHG200 | 450 t/h | 15 kw | 1-3 m/s |

| WRHG260 | 1000 t/h | 30 kw | 1-2 m/s |