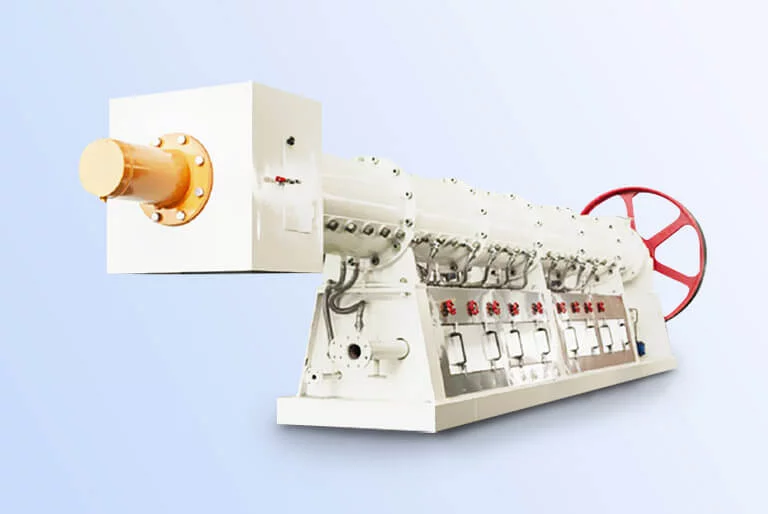

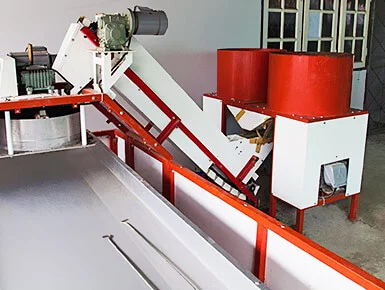

Oil materials are fed into the inlet of the extrusion machine through the magnetic chute by the spiral quantitative feeder. The steam is added to the extruder cylinder through the direct steam throttle value.

The main spiral shaft, consisting of broken tooth screws, rotates in the cylinder to mix, press, heat, shear, and rub oil material. Cells of oil material are destroyed, and the oil in cells is fully exposed.

The oil material is extruded from the mold hole on the template at high temperature and high pressure. When they are extruded out, the pressure suddenly decreases as well as the moisture evaporates rapidly, which causes the puffing of oil material.

Advantages of oilseeds extrusion extruder.

- Improve the productivity of the oil solvent extractor.

- Increase oil solvent extraction rate and shorten oil extraction time.

- Extrusion materials absorb less solvent, so it is easy to dissolve.

- Increase the concentration of mixed oil, so decrease the load of evaporation of mixed oil.

- Enzymes in oil materials are passivated after extrusion, so the quality of extracted oil is improved.

- The processing capacity of the flaking machine is improved.

- Reduce energy consumption in the oil solvent extraction processing workshop.

| Model | Low oil yield(t/d) | Height oil yield(t/d) | Power(kW) |

|---|---|---|---|

| YJP16 | 100-150 t/d | 60-80 t/d | 37-55 kw |

| YJP20 | 150-350 t/d | 80-200 t/d | 75-90 kw |

| YJP25 | 350-600 t/d | 200-400 t/d | 90-110 kw |

| YJP30 | 600-1200 t/d | 400-600 t/d | 132-160 kw |

| YJP35 | 1200-1800 t/d | 600-900 t/d | 220-250 kw |