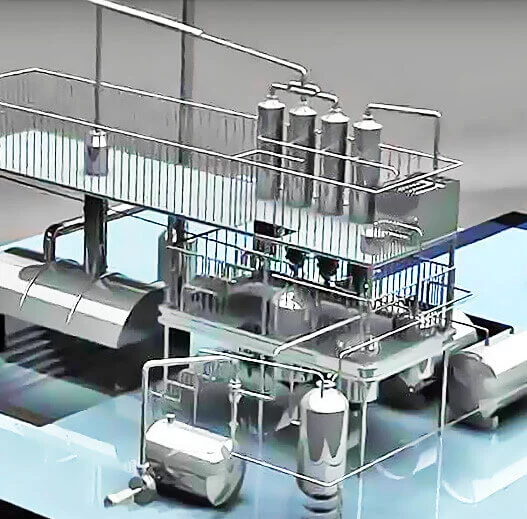

Huatai Group always focuses on customer satisfaction and quality

- Professional Customization

- Global Service

A sale is the first step, not the last. We have an after-sale service team to provide our valuedclients with timely support.Wherever you are from, whatever you need, we're happy to help you.

GET A QUOTE-

![]() Service Coverage

Service Coverage

From scheme forming to the customer site testing, we provide customers with perfect service system that form comprehensive, three-dimensional quality coverage.

-

![]() FAQ

FAQ

Over the years we have kept a record ofcommon questions asked by Huatai usersand potential users.