Cleaning

Use magnetic separators, cleaning screens and stone removers to remove impurities such as iron filings, stones, grass, and soil from sunflower seeds.

Huatai Group's sunflower oil production line converts sunflower seeds into high-quality edible oil facilities, integrating advanced technology and mature processes. It is committed to achieving efficient, high-quality oil extraction goals. (Related Post: Sunflower seed processing plant cost >>)

The overall architecture of the sunflower oil production line covers four closely connected systems: sunflower seed pretreatment, oil extraction core process, sunflower seed crude oil refining, and finished oil filling and packaging. Each system works together to build a complete and efficient production system.

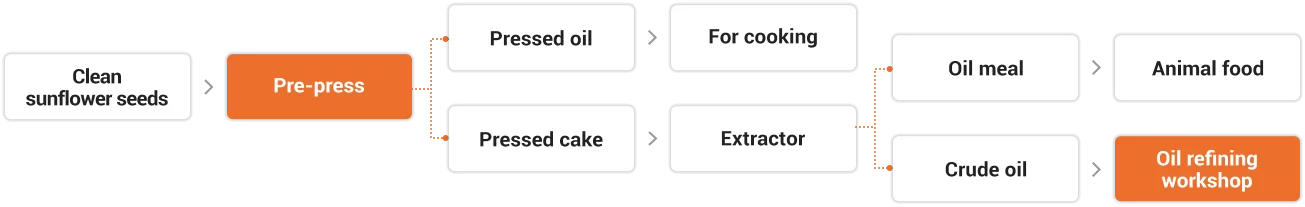

Three key stages: sunflower seed pressing, sunflower seed cake extraction, and sunflower seed crude oil refining.

The pure sunflower kernels after screening and shelling enter the screw press. The precise control of temperature and pressure is extremely important. The appropriate conditions can ensure a high oil yield and a high purity of crude oil.

The sunflower seed cake after pressing still contains a certain amount of oil. To further increase the oil yield, adopt the extraction process.

Whether it is pressed crude oil or extracted crude oil, it contains impurities such as phospholipids, free fatty acids, pigments, odor substances, and possible residual solvents, so it needs refining.

Use magnetic separators, cleaning screens and stone removers to remove impurities such as iron filings, stones, grass, and soil from sunflower seeds.

Use a shelling machine to remove the shells of sunflower seeds to prevent the shells of sunflower seeds from absorbing oil and reducing oil loss, while preventing the sunflower shells from affecting the operation of the equipment and damaging the equipment.

The shelled sunflower seeds are transported to the flaking machine for flaking, rolled into thin slices, destroying cell tissues, and making it easier for oil to flow out.

Steaming and frying can adjust the temperature, humidity and internal structure of sunflower seeds to achieve better oil extraction effects.

The fried sunflower seeds are first transported to the pre-pressing machine for pressing. The oil press uses the external force of mechanical extrusion to make the oil in the sunflower seed cake flow out, obtain pressed sunflower seed oil, and at the same time make the residual oil and powder degree in the pressed cake reach the extraction process indicators.

The steps of sunflower oil refining mainly include degumming, decolorization, deodorization, and dewaxing. The refined oil has a light color, high nutritional value, and good taste.

The refining workshop needs to be equipped with a complete set of sunflower seed oil refining equipment, the main equipment of which includes: a dephosphorization and degumming Dehydration pot, decolorization pot, soap stock pot, deodorization tower, clay tank, crude oil tank, filter oil pump, vibration filter, air compressor, heat exchanger, thermal oil furnace, etc.

The sunflower oil after the deodorization process also contains a small amount of wax, which is pumped into the pre-cooled crystallization tank and cooled at a certain cooling rate within 8 hours. After the oil is cooled and crystallized to a certain temperature, the crystal retention time is maintained for 12 hours in the crystallization tank. After that, the oil and wax are separated by a filter press, and the resulting oil is finished with sunflower oil, which meets the standard of high-grade edible oil.

Compared with other single oil pressing methods, the oil pre-pressing and extraction process has the advantages of high oil yield, good oil quality, good economic benefits, strong adaptability of oil seeds, and flexible production.

This process can also be used to extract oil from peanuts, rapeseed, sunflower seeds, and other seeds or nuts.

A full continuous refining process has a production capacity of more than 50 tons per day. With characteristics of high refining yield and low consumption of auxiliary materials, a full continuous refining process can meet the requirements of deep processing of products. The process requires continuous operation, which is suitable for larger-scale production of continuous production enterprises.

Before being pressed by the oil press, sunflower seeds need to go through pro-cesses such as cleaning, shelling, crushing, steaming, and frying, and then sent to the oil press for pressing to extract oil. Therefore, the equipment that needs to be equipped in the sunflower oil pressing workshop includes vibrating screens, designers, crushers, oil presses, etc. (Related Product: Sunflower oil press machine >>)

A sale is the first step, not the last. We have an after-sale service team to provide our valuedclients with timely support.Wherever you are from, whatever you need, we're happy to help you.

From scheme forming to the customer site testing, we provide customers with perfect service system that form comprehensive, three-dimensional quality coverage.

Over the years we have kept a record ofcommon questions asked by Huatai usersand potential users.