Canola Oil Production Line

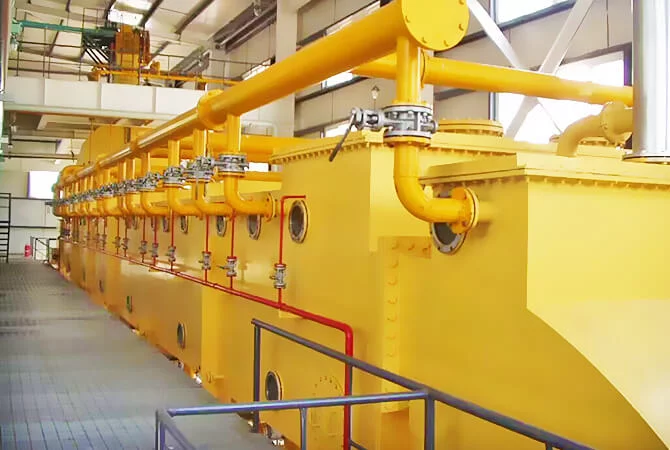

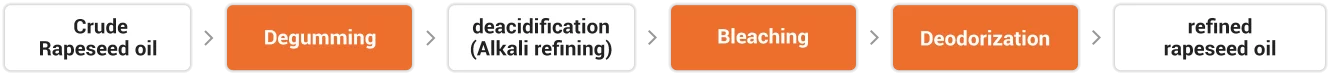

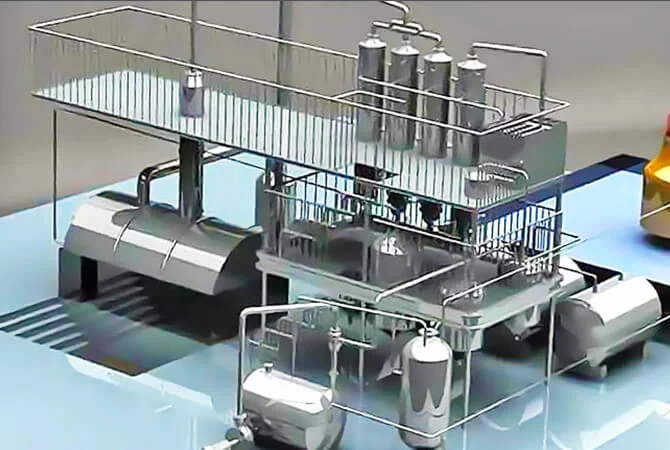

Canola oil production line is used to extract, refine, and process edible canola oil from canola. Covering raw material pretreatment, pressing/extraction oil extraction, refining and processing, and by-product processing.

Huatai Group's canola oil processing plant is based on high efficiency, automation, and environmental protection. And combined with an intelligent control system. It can meet the production needs of different scales while ensuring product quality and safe production.

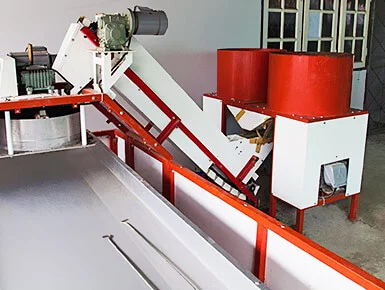

Huatai Group canola oil pressing system includes cold pressing and hot pressing. Cold pressing is low temperature pressing retains the natural flavor and nutrients of canola (residual oil rate 15-18%). Hot pressing is spiral pressing after steam heating (temperature 110-120℃) to increase the oil yield (residual oil rate ≤10%).